Who We Are

Yantong Tech is a China-based manufacturing facility specializing in high-precision gears and transmission components. We support global equipment with reliable drivetrain elements through authentic manufacturing and continuous improvement.

We don't compete with "leading slogans"—we focus on making our clients feel more confident. Our team of 96 professionals combines manufacturing expertise with quality control, providing full traceability from material procurement to final inspection.

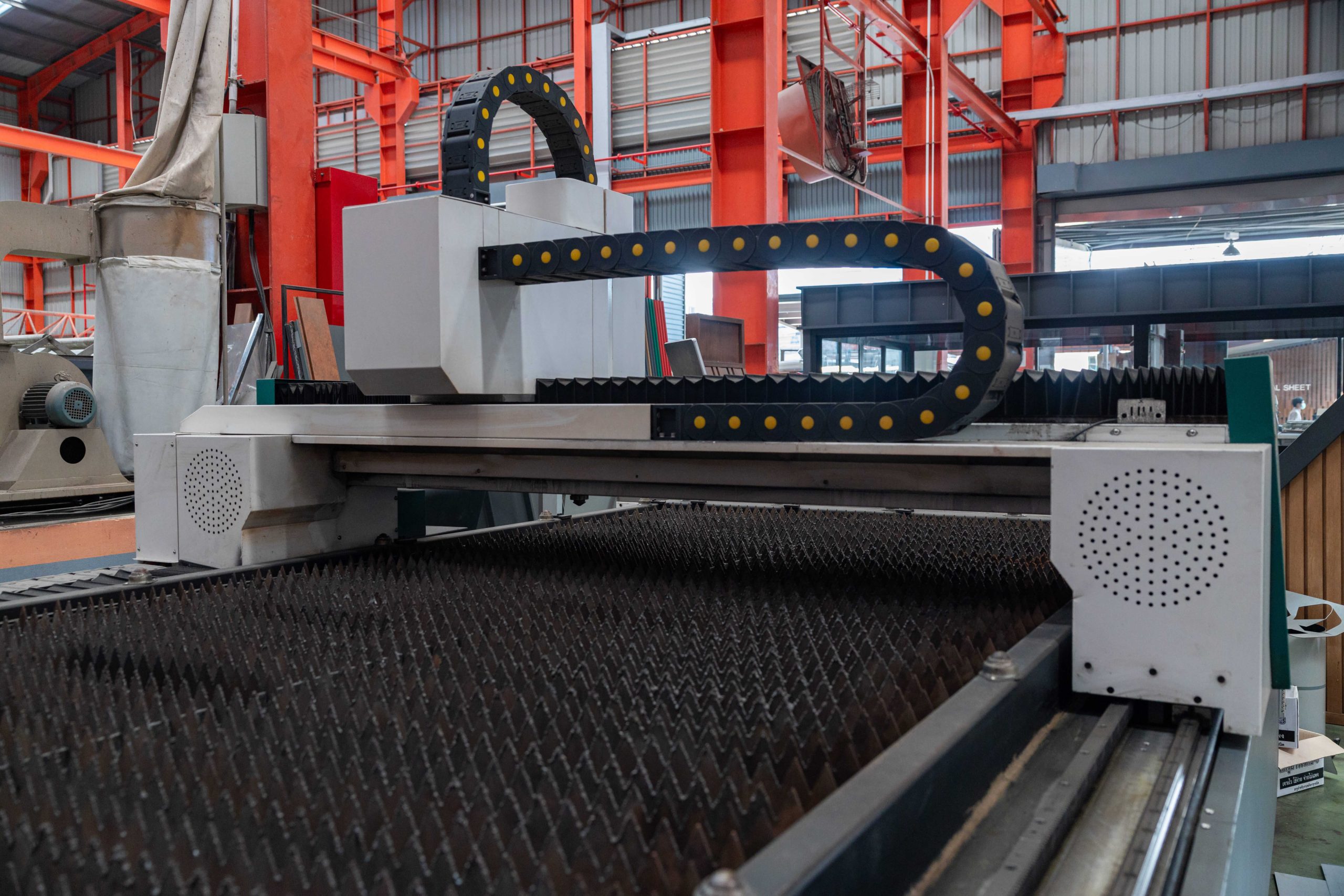

With over 50 processing equipment units, 16 engineering specialists, and comprehensive inspection capabilities, we maintain clear division of responsibilities and systematic manufacturing processes. This enables us to support high-precision machining, flexible production, and stable technical communication.

Mission & Philosophy

Through authentic manufacturing and continuous improvement, we help equipment run longer with fewer breakdowns and less rework.

Mission

Through authentic manufacturing and continuous improvement, we provide reliable transmission components for global equipment, enabling users to experience fewer shutdowns and less rework during long-term operation.

Vision

To become a gear manufacturing company trusted long-term by customers, employees, and partners—steadily producing every gear with an altruistic mindset and professional expertise.

Our Capability at a Glance

Equipment Scale

50+ processing equipment including CNC gear hobbing, shaping, grinding machines, and 5-axis machining centers.

Machining Precision

Ground gears achieve ISO 1328-6 grade. Standard production maintains 7-8 grade consistently.

Heat Treatment Capability

Carburizing, nitriding, induction hardening, and tempering. Tooth surface hardness 58-62 HRC with controlled case depth.

Inspection & Traceability

Gear measurement centers, CMM, hardness testers, and NDT equipment. Full process data archiving for batch traceability.

Quality & Inspection System

Full traceability from incoming materials to final inspection.

Incoming Inspection

Material verification, certification review, and dimensional checks.

In-Process Testing

Real-time monitoring during machining and quality control checkpoints.

Tooth Profile Testing

CMM data recording, error mapping, and batch traceability codes.

Heat Treatment Verification

Hardness testing, case depth measurement, and metallographic analysis.

Non-Destructive Testing

Magnetic particle inspection for surface and subsurface defects.

Final Inspection

Complete dimensional verification, visual inspection, and documentation.

Our Engineering & Customization Services

Custom Manufacturing

Support for 2D/3D file formats including STEP and DWG. Manufacturing from technical drawings with engineering review.

Reverse Engineering

Measurement, material analysis, and heat treatment replication for legacy parts requiring exact reproduction.

Design Optimization

Tooth profile modification, noise reduction, and service life improvement based on application conditions.

OEM/ODM Cooperation

From prototyping to mass production. Small-batch and multi-variety production capabilities for flexible cooperation.

Why Our Clients Trust Us

"Yantong Tech's engineering team truly understands our application requirements. They provided valuable tooth profile optimization suggestions that extended our gear service life by 40%. Full traceability documentation made our quality audits seamless."

"We've worked with several gear manufacturers, but Yantong Tech stands out for their honest communication and consistent delivery times. No surprise price adjustments, no quality compromises. Reliable partner for our packaging machinery line."

"Their reverse engineering capability saved our production line when the original supplier discontinued a critical gear component. Yantong measured, analyzed the material, and reproduced it perfectly. Fast response and professional service."

Why Choose Yantong Tech

Engineering Communication

Engineer-to-engineer dialogue. We understand your operating conditions and optimize designs—not just quote prices.

Quality Traceability

Materials, heat treatment, and inspection data are fully recorded and traceable by batch number.

Stable Delivery

Parallel processes and rolling inventory systems ensure reliable delivery schedules.

Honest Pricing

Reasonable pricing based on drawings and risk assessment—no "ultra-low price tactics."

Long-Term Partnership

Focus on equipment lifecycle cost (LCC) and sustainable relationships, not one-time transactions.

How We Achieve Long-Term Sustainability

To Customers

- Stable delivery schedules

- Traceable manufacturing processes

- Reliable technical documentation

To Employees

- Respect for craft time and skills

- Continuous skill development

- Safe working environment

To Society

- Energy conservation and waste reduction

- Minimized material waste

- Honest business practices

Frequently Asked Questions

Yes. We support small-batch and multi-variety customization with engineer-to-engineer collaboration. We can perform tooth profile modifications and manufacturing feasibility optimizations.

Standard parts: 20-35 days delivery. Custom or complex heat treatment parts depend on the project specifics. Production schedule is locked once drawings are confirmed.

We provide tooth profile/lead error reports, material and heat treatment reports, NDT and dimensional inspection reports, all traceable by batch number.

Currently exporting to 20+ countries in Europe, North America, Southeast Asia, and the Middle East.

Yes. We provide OEM production and reverse engineering services for multiple European and American clients.

Ready to Start Your Project?

Our engineering team is here to understand your requirements, review your technical drawings, and provide professional manufacturing solutions. Whether you need precision gears, custom transmission components, or reverse engineering services—let's discuss how we can support your equipment's long-term reliability.