Reliable Industrial Gears & Transmission Components for Global Equipment

Precision manufacturing, traceable quality control, and engineering-focused communication — helping OEMs and maintenance teams reduce downtime and extend service life.

Why Engineers and Procurement Managers Choose Yantong Tech

Four core capabilities that support your long-term equipment stability

Predictable Lead Time

Standard parts with safety stock, custom orders with transparent scheduling and milestone tracking.

Traceable Quality

Material certificates, heat treatment reports, gear measurement data — full batch traceability from raw material to shipment.

Engineering-Friendly Communication

Our manufacturing engineers speak directly with your technical team, understanding working conditions before proposing solutions.

Honest & Sustainable Partnership

Realistic pricing based on drawings and risk assessment — no bait-and-switch, no hidden costs, just steady collaboration.

What Challenges Do Your Equipment and Procurement Teams Face?

Industry-specific pain points and how Yantong Tech addresses them

Packaging Machinery

Noise and backlash in high-frequency start-stop cycles affect filling precision and operator comfort.

Yantong provides precision-matched worm gear sets with controlled backlash and surface finish, ensuring smooth operation and low noise over extended duty cycles.

Wind Power Equipment

Yaw and pitch systems demand high reliability in harsh environments; unexpected failures lead to costly downtime and difficult maintenance access.

Yantong supplies planetary and internal gears with validated heat treatment and documented tooth profile accuracy, designed to withstand continuous load and environmental stress.

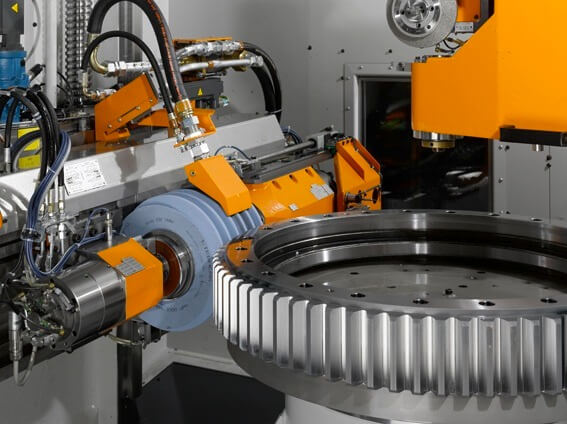

Mining & Heavy Equipment

Large girth gears in rotary kilns and ball mills face high shock loads and require maintainable, long-life components to minimize production interruptions.

Yantong offers girth gears and internal gears with controlled case depth and surface integrity, supported by full material traceability and NDT reports for predictable service life.

Comprehensive Gear Portfolio for Diverse Industrial Applications

Nine core product categories covering automation, heavy machinery, renewable energy, and material handling

Worm Gear

For packaging, food processing, and automation tooling requiring low-speed, high-torque, and quiet operation.

Bevel Gear

For construction machinery, automotive differentials, and right-angle power transmission systems.

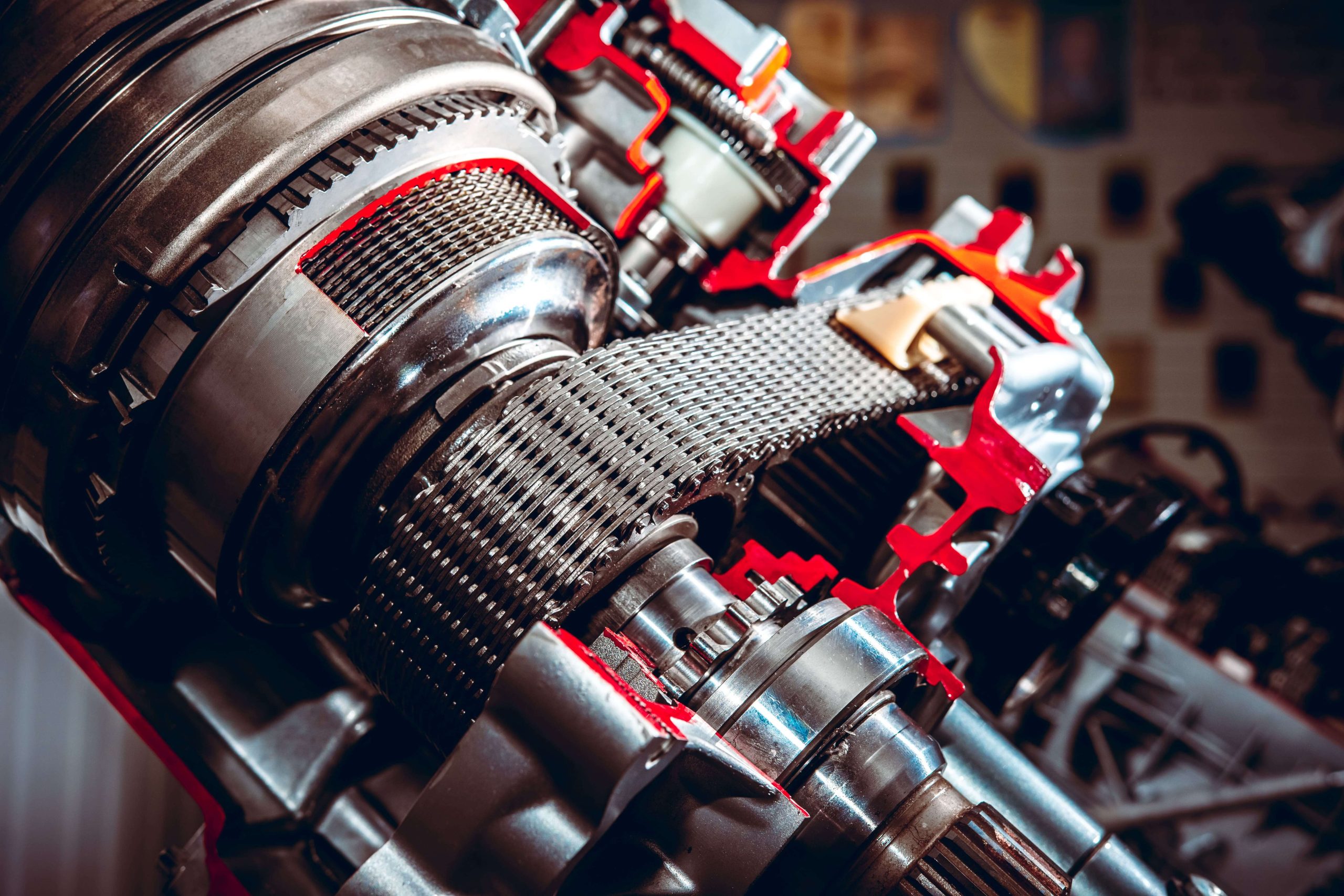

Planetary Gear

For tower cranes, wind turbine yaw/pitch drives, and heavy-duty reduction units.

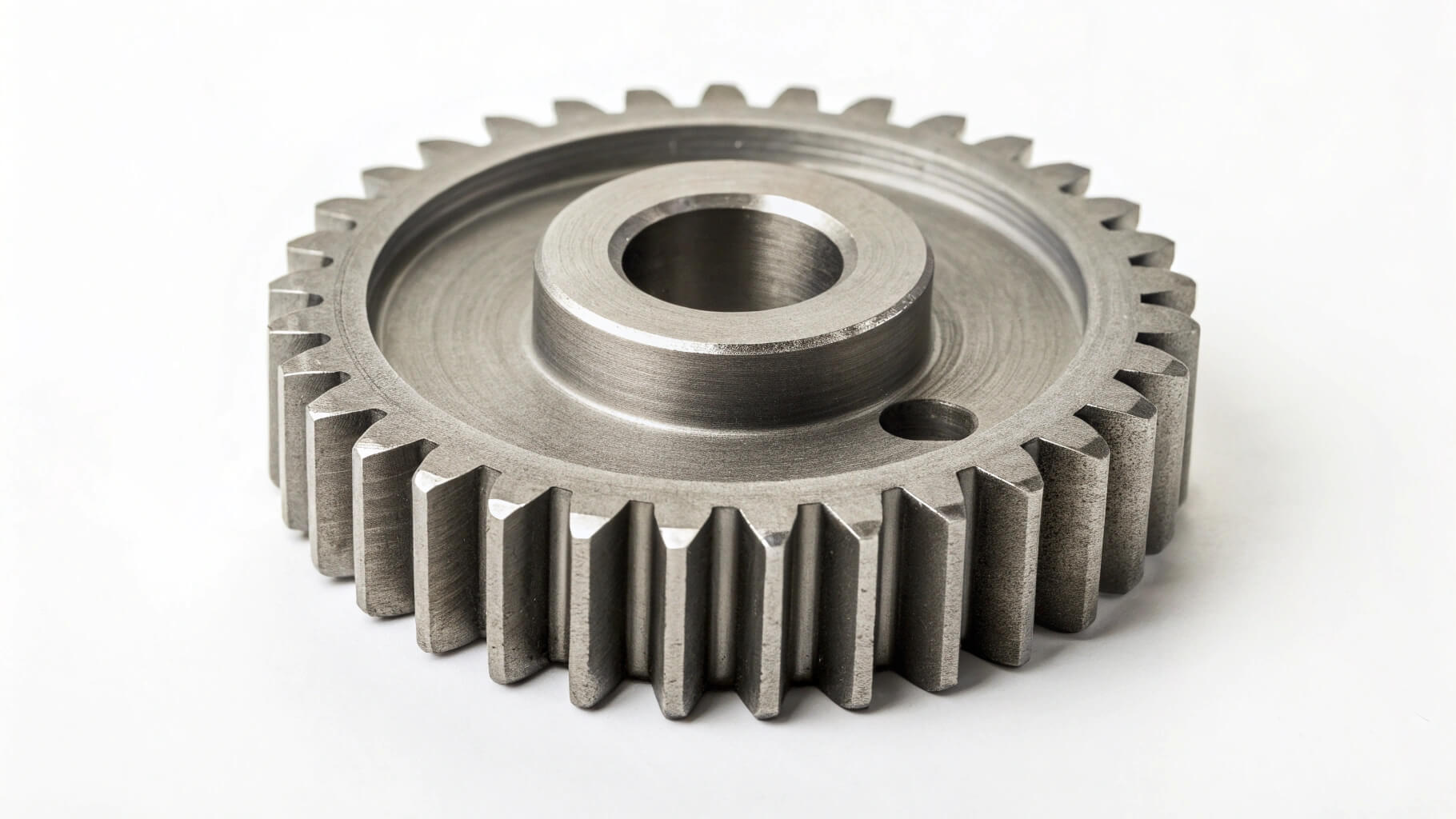

Spur Gear

For general machinery, conveyor lines, gearboxes, and agricultural equipment.

Helical Gear

For smooth, quiet power transmission in industrial reducers and material handling systems.

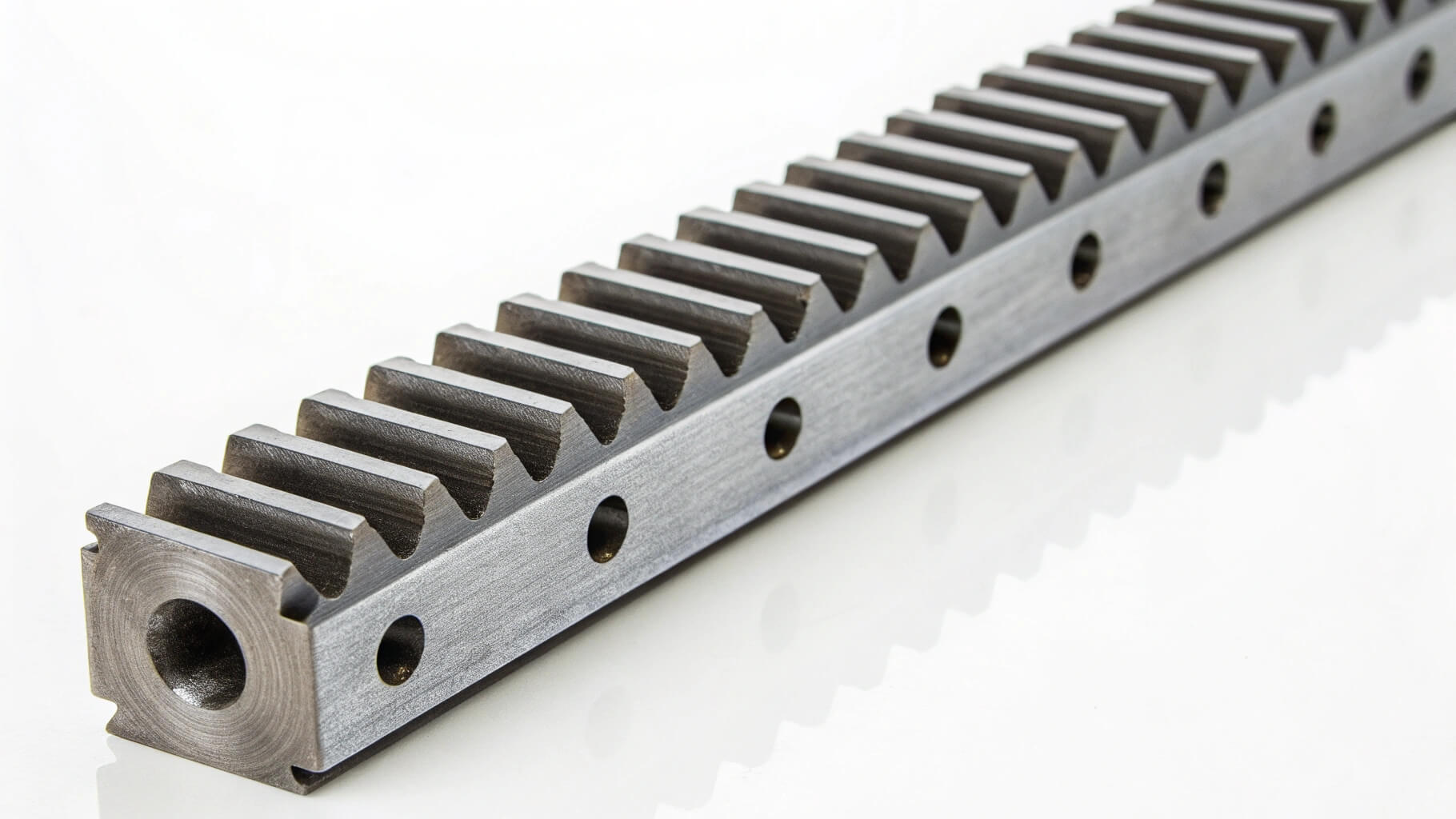

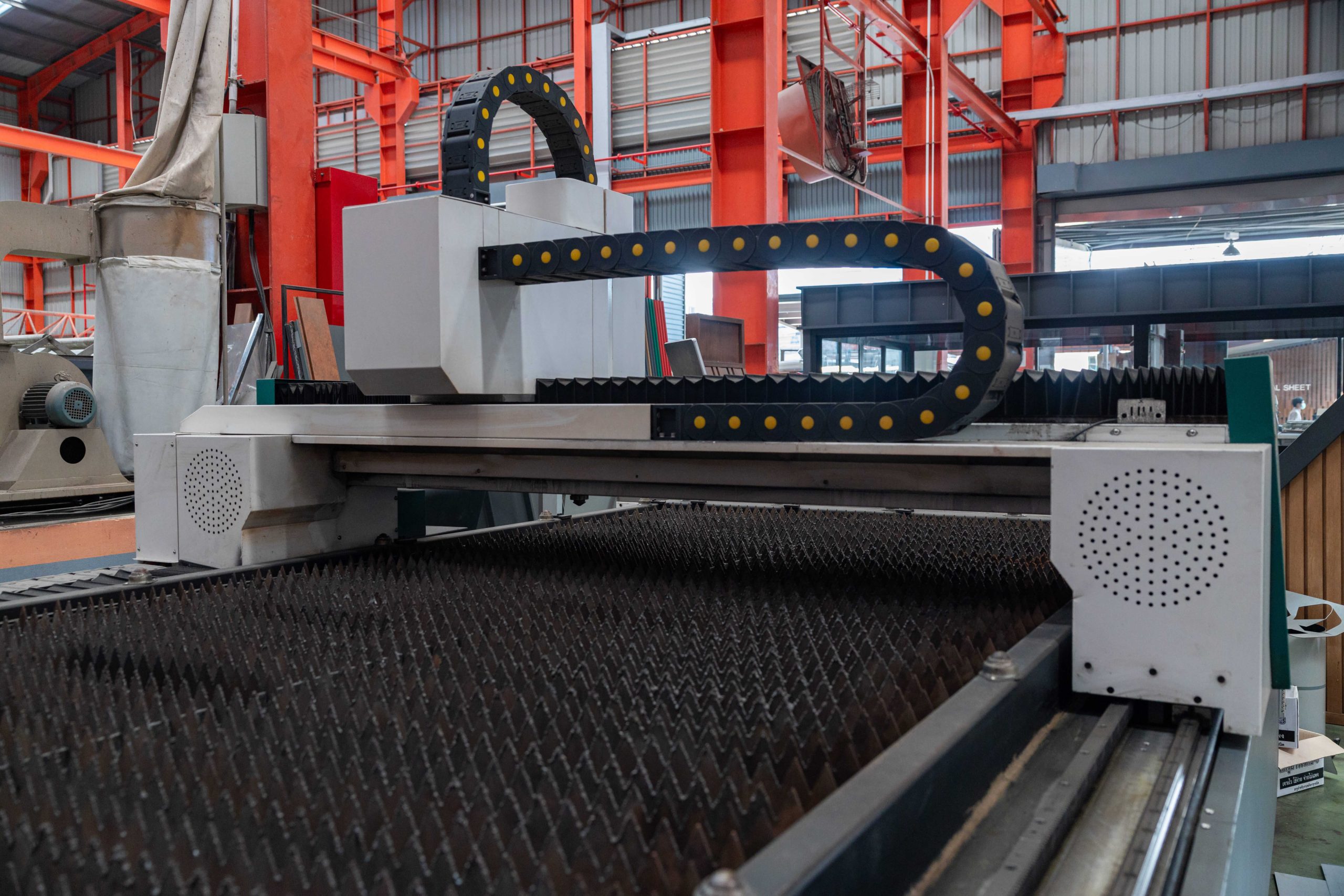

Gear Rack

For CNC machine tools, laser cutting systems, automated doors, and parking solutions.

Spiral Bevel Gear

For heavy-duty drive systems requiring smooth engagement and high load capacity.

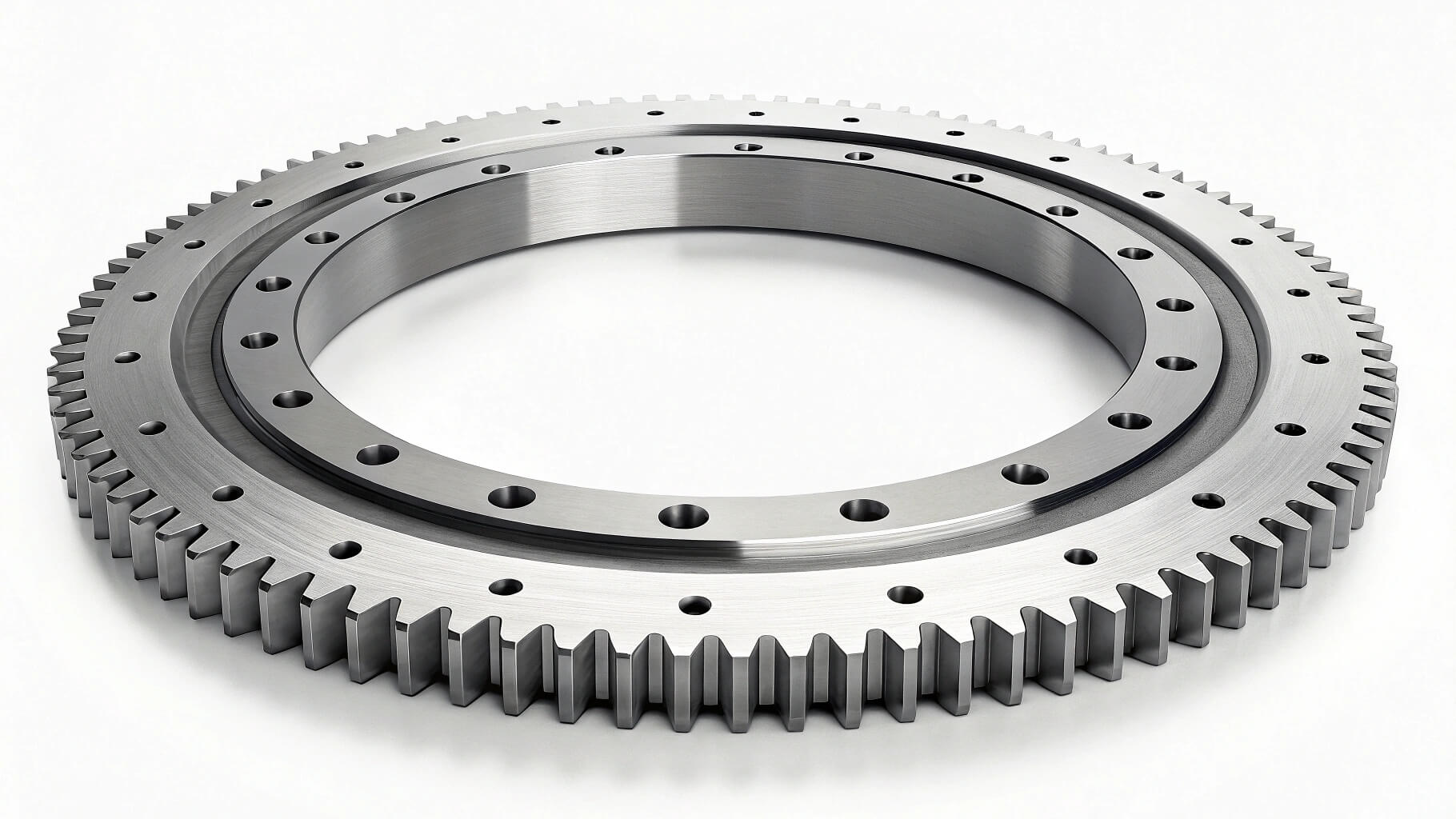

Internal Gear

For planetary systems and compact transmission assemblies.

Girth Gear

For rotary kilns, ball mills, and large rotating equipment prioritizing long-term stability.

A Manufacturing Partner You Can Trust Over Time

Founded with the commitment to deliver real manufacturing and continuous improvement, Yantong Tech serves as a reliable partner for global equipment manufacturers and maintenance teams. With 96 dedicated employees — including 50 production personnel, 16 process and technical engineers, 10 quality and inspection specialists, and 11 sales and customer service staff with engineering backgrounds — we maintain a clear division of labor and a traceable production system.

Our mission is simple: provide reliable transmission components through genuine manufacturing and continuous improvement, helping equipment run longer with fewer breakdowns and less rework. We focus not on slogans, but on stability, traceability, and engineering-focused communication that earns peace of mind from our customers.

Learn More About UsFrom Raw Material to Finished Gear: A Transparent Manufacturing Chain

Six core stages ensuring quality control and traceability at every step

Material Inspection

Incoming steel validated with mill certificates; hardness and chemical composition verified before release to production.

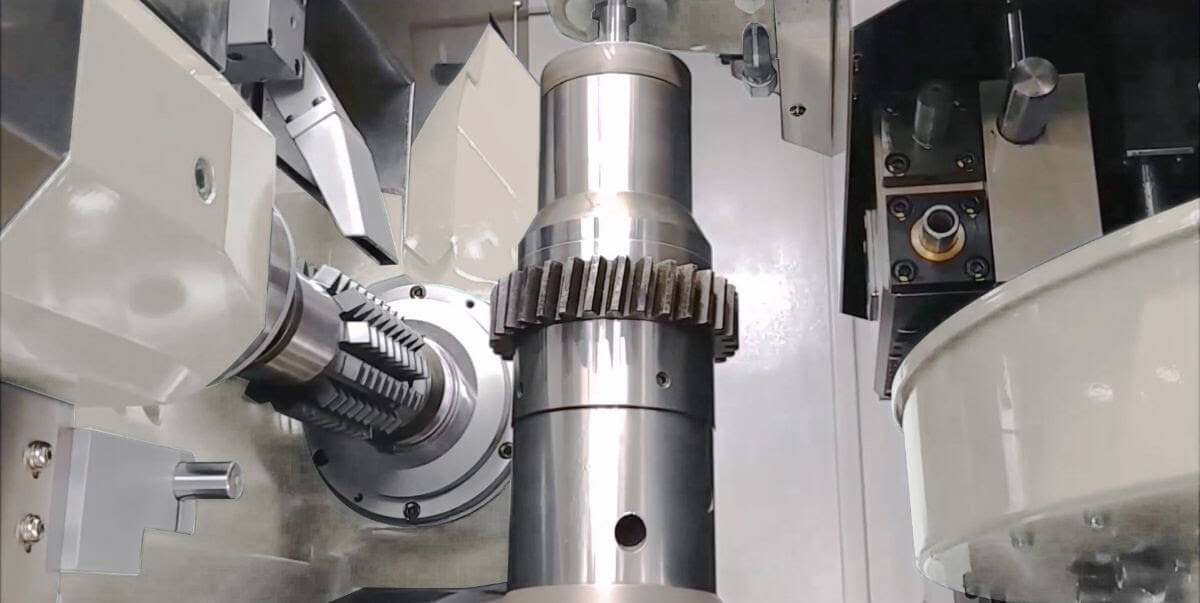

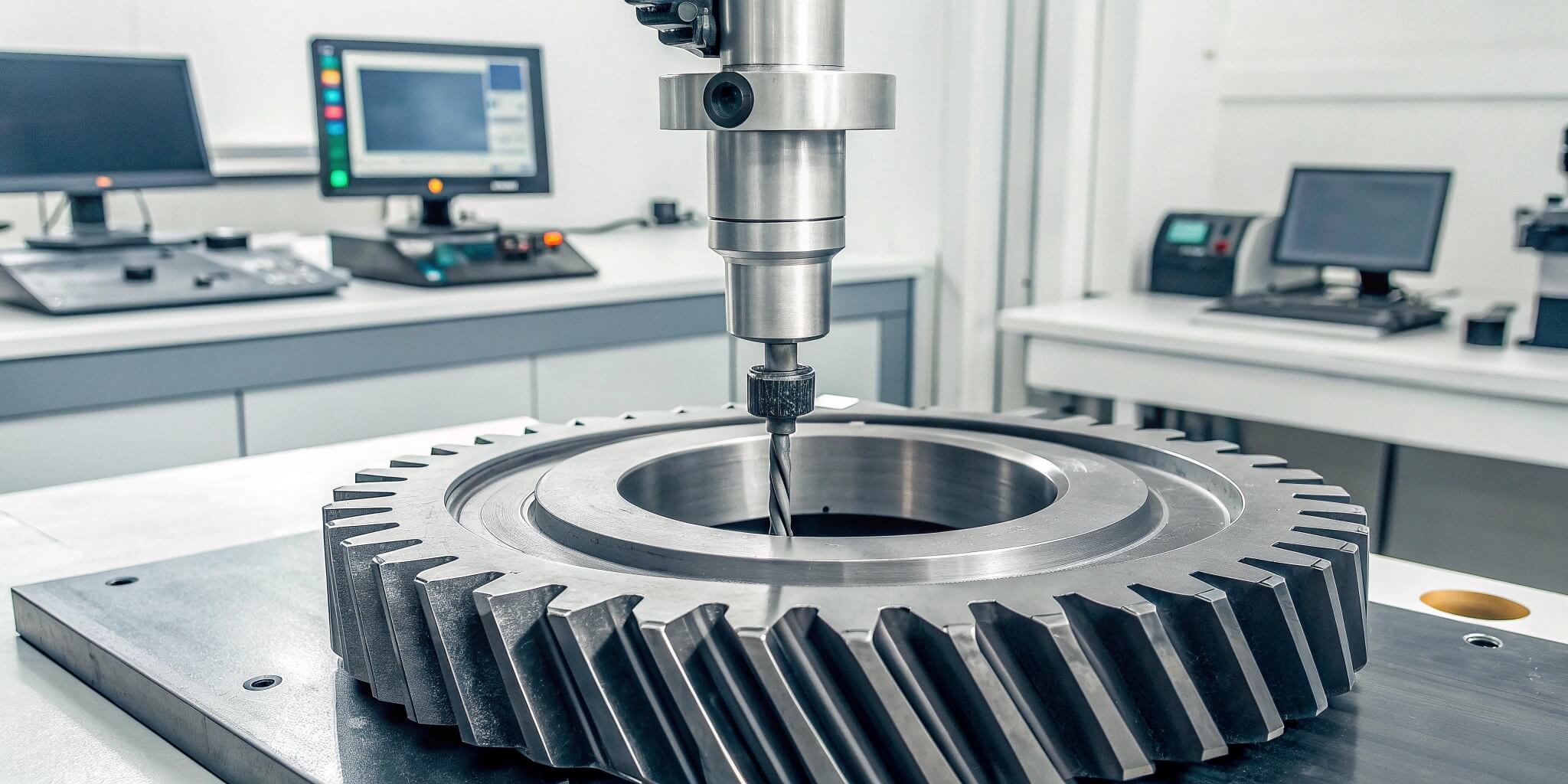

Precision Machining

CNC gear hobbing, shaping, milling, and turning with in-process dimensional checks to maintain tolerance consistency.

Heat Treatment

Carburizing, quenching, nitriding, or tempering per drawing specs; process curves and case depth documented for traceability.

Gear Grinding

CNC gear grinding for precision parts to ISO 1328 Grade 6-7; involute profile, lead, and pitch controlled and measured.

Final Inspection

Gear measurement center, CMM, hardness testing, and NDT (magnetic particle or ultrasonic) with full data recording.

Packing & Shipping

Protected packaging with batch labels, inspection reports, and material certificates prepared for export documentation.

Precision Manufacturing and Traceable Quality Control

Six-stage inspection flow ensuring consistency from material to shipment

Incoming Material

Mill certificates verified; hardness and chemical composition tested before acceptance.

Machining Control

First-piece inspection and in-process dimensional checks to maintain tolerance stability.

Heat Treatment Check

Process curves recorded; case depth and surface hardness validated per specification.

Gear Measurement

Involute profile, lead, pitch, and runout measured on gear measurement center; data archived by batch.

Surface Inspection

Magnetic particle or ultrasonic testing for critical parts; surface roughness verified as required.

Final Report

Inspection certificate, material traceability, and heat treatment report packaged with shipment.

Industries We Serve

Delivering precision gears to diverse sectors worldwide

Packaging Machinery

Worm gears and spur gears for high-frequency filling, sealing, and labeling equipment.

Wind Power

Planetary and internal gears for yaw, pitch, and main drive systems requiring long-term reliability.

Mining & Heavy Equipment

Girth gears and bevel gears for rotary kilns, ball mills, and excavation machinery.

Agricultural Machinery

Helical and spur gears for tractors, harvesters, and material handling systems.

Automation Equipment

Gear racks and precision pinions for CNC systems, laser cutting, and automated guided vehicles.

Material Handling

Conveyors, elevators, and crane drives utilizing helical, worm, and bevel gear solutions.

Automotive Components

Spiral bevel gears for differentials and transmission assemblies.

Food & Beverage

Stainless and coated gears for mixers, conveyors, and processing lines.

Energy & Petrochemical

Heavy-duty gears for pumps, compressors, and rotating equipment in harsh environments.

What Our Clients Say

Trusted by engineers and procurement managers across three continents

Mark Steiner

Mechanical Design Engineer & Purchasing Manager, Germany

"Yantong Tech provides not just gears, but engineering dialogue. They understand our drawings, ask the right questions, and deliver with full traceability. That consistency is what we need for long-term cooperation."

Michael Johnson

Purchasing Director, United States

"Lead time reliability and responsive communication set Yantong apart. When we have an issue, they own it and resolve it quickly. That's the kind of partner we can scale with."

Somchai Anurat

Operations Manager, Thailand

"We value suppliers who communicate honestly and deliver consistently. Yantong Tech has proven to be a reliable partner for our packaging machinery projects — reasonable pricing, stable quality, and respectful service."

Custom Engineering and Manufacturing Collaboration

We understand working conditions, not just drawings — supporting OEM, ODM, and reverse engineering with feasibility analysis.

Reverse Engineering

Sample measurement, material identification, and heat treatment replication with manufacturability recommendations.

OEM/ODM Production

Small-batch and multi-variant production supported; prototyping and pilot runs welcomed for design validation.

Parametric Modeling

3D modeling and tooth profile modification based on load conditions and desired contact patterns.

Manufacturability Optimization

Proactive suggestions on tolerances, material selection, and heat treatment to balance cost and performance.

Quality Certifications and Regulatory Compliance

Recognized quality systems and material compliance for international markets

ISO 9001

Quality management system certified; documented procedures for material traceability, process control, and corrective action.

IATF 16949 Methods

Selected projects utilize APQP, PPAP, MSA, and SPC principles for automotive-level quality assurance.

RoHS / REACH

Material declarations available upon request for European and North American compliance requirements.

Material Certificates

Mill test reports (EN 10204 3.1) provided for critical components; chemical composition and mechanical properties documented.

Third-Party Testing

Independent inspection and testing services supported; SGS, TÜV, and other accredited labs can be coordinated.

Full Traceability

Batch coding system links each shipment to raw material lot, heat treatment cycle, and final inspection records.

How to Work With Yantong Tech

A clear, five-step process from inquiry to delivery

Inquiry & Drawing Review

Submit drawings or samples; our engineers review for feasibility and clarify specifications.

Quotation & Lead Time

Receive transparent pricing based on material, process, and volume; delivery schedule confirmed.

Sample Approval

First article inspection report and sample parts provided for validation before production.

Production & QC

Manufacturing executed per process plan; in-process checks and final inspection documented.

Delivery & Support

Parts shipped with full documentation; remote technical support available for installation and feedback.

Frequently Asked Questions

Quick answers to common inquiries about our capabilities and processes

Get in Touch

sales@yantongtech.com

Phone

+86-18003112232

Address

No. 363, South Tiyu Street, Yuhua District, Shijiazhuang City, Hebei Province, China

"Send your drawing, get an engineering reply within 24 hours."